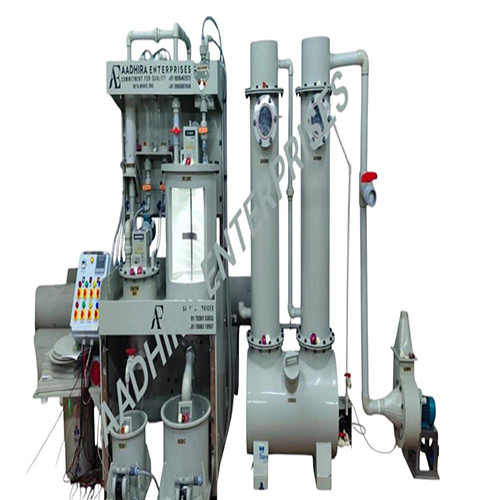

Gold Jewellery Refining Machine

Gold Jewellery Refining Machine Specification

- Product Type

- Gold Jewellery Refining Machine

- General Use

- Industrial

- Material

- Other

- Automatic

- Yes

- Control System

- PLC Control

- Voltage

- 220-440 Volt (v)

- Feature

- Lower Energy Consumption

- Color

- Grey Paint Coated

Gold Jewellery Refining Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About Gold Jewellery Refining Machine

Features:

- With Any Desired Capacity as per customers choice

- No Smell, No Smoke, 100% Pollution free

- No Vibration No Sound

- Purity of 99.99% and 100% Recovery

- Compatible to be used in showroom and jewellery shops

- Low maintenance cost

- Easy and standard working

- Scrubber unit PH7 Approved

- Single user operating system

- Safe and Secure

- Recycling and Refining of All Types Of Scrap and Waste Old Jewellery / Sweeping Dust / Polishing Waste etc.

- Chemical flooring (as per requirement)

- Feature of acid auto filling is in-built in our machine.

- Pump and motor used are of imported quality.

- Single cycling condenser system.

- Chemical mixing and dissolution: A cylinder or tank where gold scrap is dissolved in an acid solution, such as the aqua regia method (a mixture of nitric and hydrochloric acids).

- Condenser system: A system that cools and recovers some of the acid, and neutralizes fumes to reduce pollution.

- Scrubber unit: A component to further clean waste gas, with some approved by standards like PH7.

- Filtration and separation: Machinery like a filter press or a decanter centrifuge is used to separate the gold-bearing solution from other materials.

- Precipitation: Chemicals are added to the solution to precipitate the gold as a powder or sludge.

- Filtration and rinsing: The gold powder is then filtered and rinsed to remove residual chemicals.

- Melting and casting: An induction furnace may be used to melt the purified gold powder and cast it into bars.

- Automation and safety: Modern machines often have features like acid auto-filling, single-user operation, low maintenance, and safety features to make the process safer and more user-friendly.

- Preparation: Scrap gold jewelry is analyzed and prepared for the process.

- Dissolution: The gold is dissolved in an acid solution, often aqua regia, which separates it from other metals.

- Neutralization and separation: Fumes are neutralized, and the solution is processed to separate the dissolved gold.

- Precipitation: The gold is precipitated out of the solution as a solid.

- Filtering and washing: The precipitated gold is filtered and washed to remove impurities.

- Purification and recasting: The pure gold is then melted and recast into new forms.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gold Refinery Machine Category

Industrial Gold Refining Plant

Price 710000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Product Type : Industrial Gold Refining Plant

Color : Grey Paint Coated

Feature : Lower Energy Consumption

Aqua Regia Gold Refinery Machine

Price 651000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Product Type : Aqua Regia Gold Refinery Machine

Color : Grey Paint Coated

Feature : High Efficiency

Automatic Gold Refining Machine And Plant

Price 565000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Product Type : Automatic Gold Refining Machine And Plant

Color : Grey

Feature : Lower Energy Consumption

Beta Model Gold Refinery Machine

Price 551000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic : Yes

Product Type : Beta Model Gold Refinery Machine

Color : Grey

Feature : Lower Energy Consumption

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS