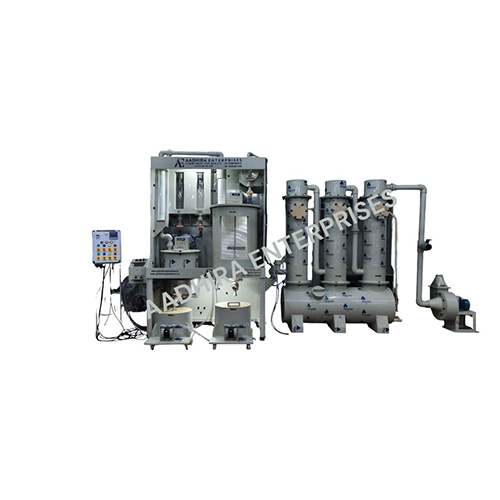

Gold Recovery Refining Equipment

Gold Recovery Refining Equipment Specification

- Product Type

- Gold Recovery Refining Equipment

- Material

- Stainless Steel

- Capacity

- 1-1000 Kg

- Computerized

- No

- Automatic

- Yes

- Voltage

- 220 Volt (v)

- Color

- Grey

Gold Recovery Refining Equipment Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

About Gold Recovery Refining Equipment

FAQs of Gold Recovery Refining Equipment:

Q: What is the voltage requirement for this equipment?

A: The voltage requirement for this equipment is 220 Volt.Q: Is this equipment automatic?

A: Yes, this equipment comes with automatic functionality.Q: What is the material used in this equipment?

A: This equipment is constructed with stainless steel material.Q: What is the capacity range of this equipment?

A: The capacity of this equipment ranges from 1 to 1000 Kg.Q: Is this equipment computerized?

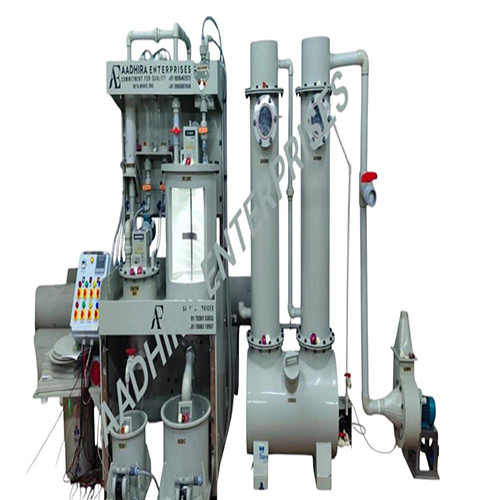

A: No, this equipment is not computerized.- Reaction and dissolving vessels: These are typically made from corrosion-resistant materials like titanium, specialized plastics, or stainless steel, and hold the chemical solutions used to dissolve gold and other metals.

- Filtration systems: These separate solid impurities from liquid solutions. Examples include filter presses and candle filters, which capture microscopic particles.

- Scrubbers: These are crucial for neutralizing and removing harmful fumes (like acid fumes) generated during the refining process, often using wet or dry absorption methods.

- Electrolytic refining equipment: This uses electrolysis to achieve ultra-high purity. It includes electrolytic cells with anodes (impure gold) and cathodes (pure gold) and a rectifier to provide the necessary direct current.

- Fume control and waste handling: Systems often incorporate features for safe chemical handling, acid auto-filling, and comprehensive waste recovery systems to minimize environmental impact and maximize yield.

- Refining processes:

- Aqua regia refining: Dissolves gold from scrap using a mixture of nitric and hydrochloric acids. It is suitable for a range of materials and offers a balance of efficiency and cost-effectiveness, often followed by a reduction process to recover the gold powder.

- Electrolytic refining: Uses an electric current to separate gold from other metals in solution, leading to a higher purity product. This is often used in more advanced or high-capacity operations.

- Deplating: A process specifically designed to remove gold plating from items like circuit boards, recovering the gold for further refining.

- Material versatility: Equipment can process a wide variety of materials, including scrap jewelry, electronic waste (like CPUs, motherboards, and phones), industrial catalysts, and floor sweeps from jewelry polishing.

- Purity levels: Equipment is designed to achieve high purity, with many systems capable of producing gold at 99.99% purity or higher.

- Capacity: Systems are available in a wide range of capacities to suit different needs, from small jewelry shops to large industrial refiners.

- Automation: Both manual, semi-automatic, and fully automatic systems are available, offering different levels of control and labor requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gold Refinery Machine Category

Automatic Gold Refining Machine And Plant

Price 565000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220440 Volt (v)

Color : Grey

Product Type : Automatic Gold Refining Machine And Plant

Feature : Lower Energy Consumption

Beta Model Gold Refinery Machine

Price 551000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220440 Volt (v)

Color : Grey

Product Type : Beta Model Gold Refinery Machine

Feature : Lower Energy Consumption

Gold Jewellery Refining Machine

Price 665000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220440 Volt (v)

Color : Grey Paint Coated

Product Type : Gold Jewellery Refining Machine

Feature : Lower Energy Consumption

Gold Refining Equipment

Price 641000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220 Volt (v)

Color : White

Product Type : Gold Refining Equipment

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free